SD200 BUTT FUSION MACHINE OPERATION MANUAL

Siv tau ntau yam thiab Technical Parameter

| Hom | SIB 200 |

| Khoom siv | PE, PP thiab PVDF |

| Qhov ntau ntawm txoj kab uas hla × thickness | 200mm × 11.76 hli |

| Ambient temp. | -5 ~ 45 ℃ |

| Fais fab mov | 220V ± 10%, 60Hz |

| Tag nrho tam sim no | 12 A |

| Tag nrho lub zog | 2.0 KW TSI |

| Xws li: Cua sov phaj | 1.2 KW TSI |

| Cov cuab yeej npaj | 0.8 kWs |

| Max. Kub | ≥270 ℃ |

| Qhov sib txawv ntawm qhov kub thiab txias ntawm cov phaj cua sov | ± 5 ℃ |

| Max. fusion siab | 10 40n |

| Tag nrho qhov hnyav (kg) | 35 KG |

Kev piav qhia tshwj xeeb

Ua ntej siv lub tshuab, leej twg yuav tsum tau nyeem cov lus piav qhia no kom zoo thiab ua kom zoo los xyuas kom meej cov khoom siv thiab tus neeg teb xov tooj muaj kev nyab xeeb, nrog rau lwm tus kev nyab xeeb.

3.1 Lub tshuab no tsis tuaj yeem siv los ua cov ntaub ntawv tsis muaj kev piav qhia; txwv tsis pub lub tshuab yuav puas los yog ua rau muaj kev huam yuaj.

3.2 Tsis txhob siv lub tshuab nyob rau hauv ib qho chaw uas muaj kev phom sij ntawm kev tawg

3.3 Lub tshuab yuav tsum tau ua los ntawm cov neeg ua haujlwm muaj lub luag haujlwm, tsim nyog thiab raug cob qhia.

3.4 Lub tshuab yuav tsum tau ua haujlwm ntawm qhov chaw qhuav. Kev tiv thaiv yuav tsum tau txais kev pom zoo thaum nws siv los nag lossis hauv av ntub.

34.5 Lub zog input yog nyob rau hauv 220V ± 10%,60 Hz. Yog siv cov kab txuas txuas ntxiv, cov kab yuav tsum muaj cov hlau lead txaus.

Taw qhia ntawm Tshuab

Lub tshuabmuajntawm cov txheej txheem yooj yim, cov phaj cua sov, cov cuab yeej npaj thiab kev txhawb nqa.

Kev qhia siv

5.1 Tag nrho cov cuab yeej yuav tsum tau muab tso rau ntawm lub dav hlau ruaj khov thiab qhuav kom ua haujlwm.

5.2 Ua ntej ua haujlwm, xyuas kom meej cov hauv qab no:

Lub hwj chim mov yog teev raws li lub pob tw fusion tshuab

Cov kab hluav taws xob tsis tawg lossis hnav

Cov hniav ntawm kev npaj cov cuab yeej yog ntse

Tag nrho cov twj paj nruag yog qhov qub

Txhua yam tsim nyog thiab cov cuab yeej muaj

Lub tshuab ua haujlwm zoo

5.3 Muab cov ntxig tsim nyog raws li sab nraud ntawm cov yeeb nkab / haum

5.4 Vuam txheej txheem

5.4.1 ib. Ua ntej vuam, ua ntej, xyuas seb puas muaj khawb lossis tawg ntawm cov kav dej / fittings. Yog hais tias qhov tob ntawm khawb los yog fissures tshaj 10% ntawm phab ntsa thickness, tshem tawm cov khawb los yog fissures.

5.4.2 Ntxuav sab hauv thiab sab nraud ntawm cov yeeb nkab kawg kom welded.

5.4.3 Muab cov kav dej / fittings thiab ua kom lub elongated ntev ntawm cov kav dej / fittings xaus kom welded sib npaug (kom luv li ntev tau). Lwm qhov kawg ntawm cov yeeb nkab yuav tsum tau txais kev txhawb nqa los ntawm cov chais kom txo kev sib txhuam. Fasten cov screws ntawm clamps los kho cov kav dej / fittings.

5.4.4 Muab cov cuab yeej npaj, hloov nws rau thiab kaw cov kav dej / fittings xaus los ntawm kev khiav haujlwm ob lub pas nrig tawm tsam cov cuab yeej npaj kom txog thaum txuas ntxiv thiab homogenous shavings tshwm los ntawm ob sab. Cais cov thav duab, hloov cov cuab yeej npaj thiab tshem tawm. Lub shavings thickness yuav tsum tsis pub dhau 0.2 ~ 0.5 hli thiab nws tuaj yeem hloov kho los ntawm kev kho qhov siab ntawm cov cuab yeej npaj cov hniav.

6.4.5 Kaw cov kav dej / fittings xaus thiab xyuas qhov sib dhos. Lub misalignment yuav tsum tsis txhob ntau tshaj 10% ntawm phab ntsa thickness, thiab nws yuav tsum tau txhim kho los ntawm loosening los yog zawm cov screws ntawm clamps. Qhov sib txawv ntawm ob lub yeeb nkab kawg yuav tsum tsis pub tshaj 10% ntawm phab ntsa thickness; txwv tsis pub cov kav dej / fittings yuav tsum tau npaj dua.

5.4.6 Tshem tawm cov plua plav thiab hlais ntawm cov phaj cua sov (Tsis txhob khawb PTFE txheej ntawm lub phaj cua sov).

5.4.7 Muab lub phaj cua sov tso rau hauv thav duab tom qab nws tau txais qhov kub thiab txias. Nce lub siab mus rau qhov teev los ntawm kev ua ntawm tus kov kom txog thaum lub hlaws ncav cuag qhov siab xav tau.

5.4.8 Txo lub siab rau tus nqi uas txaus kom ob sab kov nrog cov phaj cua sov rau lub sijhawm teev.

5.4.9 Thaum lub sij hawm dhau mus cais cov thav duab thiab tshem lub phaj cua sov, koom nrog ob sab kom sai li sai tau.

5.4.10 Nce lub siab kom txog thaum cov hlaws xav tau tshwm. Fasten lub xauv lub cuab yeej kom qhov sib koom ua ke txias los ntawm nws tus kheej. Thaum kawg qhib clamps thiab tshem tawm cov yeeb nkab txuas.

5.4.11 Tshawb pom qhov sib koom ua ke. Qhov sib koom ua ke yuav tsum yog qhov sib luag, thiab hauv qab ntawm qhov zawj ntawm cov hlaws yuav tsum tsis txhob qis dua cov yeeb nkab nto. Lub misalignment ntawm ob hlaws yuav tsum tsis txhob ntau tshaj 10% ntawm phab ntsa thickness, los yog vuam yog tsis zoo.

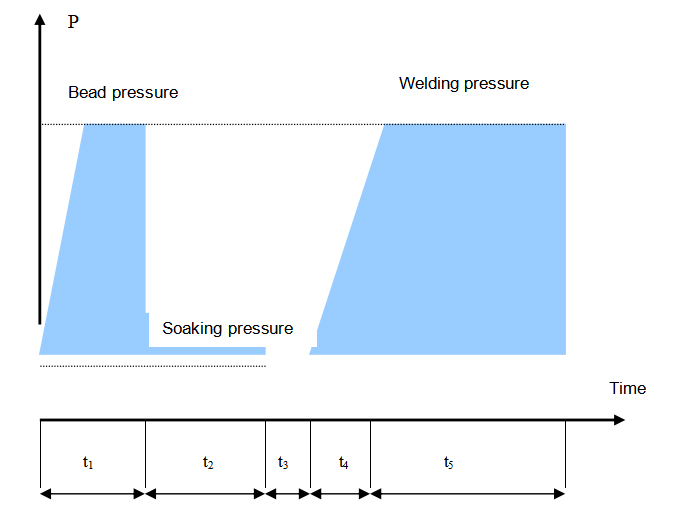

Kev siv vuam Standard (DVS2207-1-1995)

6.1 Vim tias qhov sib txawv ntawm cov txheej txheem vuam thiab cov khoom siv PE, lub sij hawm thiab lub siab sib txawv hauv ntau theem ntawm vuam. Nws qhia tau hais tias qhov tseeb welding tsis yuav tsum tau muab los ntawm cov kav dej thiab fittings'neeg tsim khoom.

| Phab ntsa thickness (mm) | Bead qhov siab (mm) | Bead build-up siab (MPa) | Soak lub sijhawm t2(sec) | Soaking siab (MPa) | Hloov-tshaj sijhawm t3(sec) | Lub sijhawm ua haujlwm siab t4(sec) | Vuam siab (MPa) | Lub sijhawm txias t5(min) |

| 0 x4.5 | 0.5 | 0.15 | 45 | ≤ 0.02 | 5 | 5 | 0.15 ± 0.01 | 6 |

| 4.5 x 7 | 1.0 | 0.15 | 45x7 0 | ≤ 0.02 | 5 x6 | 5 x6 | 0.15 ± 0.01 | 6-10 |

| 7-12 | 1.5 | 0.15 | 70-120 | ≤ 0.02 | 6 x8 | 6 x8 | 0.15 ± 0.01 | 10 ~ 16 |

| 12-19 ib | 2.0 | 0.15 | 120-190 Nws | ≤ 0.02 | 8-10 | 8-11 | 0.15 ± 0.01 | 16-24 ib |

| 19-26 ib | 2.5 | 0.15 | 190-260 Nws | ≤ 0.02 | 10 ~ 12 | 11-14 ib | 0.15 ± 0.01 | 24-32 ib |

| 26-37 ib | 3.0 | 0.15 | 260-370 Nws | ≤ 0.02 | 12-16 | 14-19 ib | 0.15 ± 0.01 | 32-45 ib |

| 37 y 50 | 3.5 | 0.15 | 370-500 Nws | ≤ 0.02 | 16 ~ 20 | 19-25 : kuv | 0.15 ± 0.01 | 45-60 |

| 50 x70 | 4.0 | 0.15 | 500-700 Nws | ≤ 0.02 | 20 ~ 25 | 25-35 | 0.15 ± 0.01 | 60-80 |

Lus Cim: Cov hlaws tsim siab thiab vuam siab nyob rau hauv daim ntawv yog qhov pom zoo interface siab, lub ntsuas siab yuav tsum tau suav nrog cov qauv hauv qab no.

Cov lus qhia:

Vuam siab(Mpa)=(Tshooj ntawm vuam yeeb nkab ×0,15n ua/mm2)/(2 ×8×8×3.14) + Luag siab

Ntawm no, 1 Mpa= 1 N/mm2